-

Home

-

About Us

-

Products

-

Solution

-

Accessories Service

-

Technicial Service

-

Additional Service

-

News

-

Blog

-

Contact Us

Leave Your Message

Rubber rolls play a vital role in various industries. They are versatile components found in manufacturing processes. These rolls are used in printing, packaging, and textiles, among others.

In printing, a rubber roll helps transfer ink evenly onto surfaces. Its texture ensures consistent quality in each print. In packaging, these rolls assist in sealing materials tightly, enhancing durability. The use of rubber rolls in textiles contributes to the smooth handling of fabric, making production efficient.

However, the effectiveness of rubber rolls can vary. Factors like wear and tear affect their performance. Regular maintenance and timely replacement are essential. Understanding the role of rubber rolls can lead to improved processes and better product quality in numerous industries.

Rubber rolls are essential components in various industrial processes. They are typically cylindrical objects covered with rubber, offering a wide range of functions. For instance, rubber rolls are used for coating, pressing, and transporting materials. The soft, flexible surface provides grip and support, making operations more efficient.

These rolls come in many shapes and sizes, tailored to specific tasks. In printing industries, rubber rolls help transfer ink evenly onto surfaces. However, wear and tear can be an issue. Over time, the rubber can degrade or lose its texture, impacting performance. Regular maintenance and inspection are critical for optimal operation.

In manufacturing, rubber rolls assist in conveying materials. They reduce vibration and noise, providing a smoother process. When a rubber roll malfunctions, it can lead to delays and increased costs. Thus, investing in quality materials and maintenance is crucial for industry reliability.

Rubber rolls are essential components in various industries. They come in different types, each with unique properties. For instance, smooth rubber rolls are often used in printing and packaging. These rolls provide excellent grip and precise application of ink. The surface texture ensures a flawless finish.

Another type is textured rubber rolls. These are commonly employed in woodworking and industrial processes. The texture helps in handling and transferring materials. They can also reduce slippage, which enhances efficiency. Different hardness levels are also available, affecting performance and durability.

When choosing rubber rolls, consider several factors. The roll's hardness can impact its application. Softer rolls offer better grip, while harder rolls provide more durability. However, too hard a roll can lead to material damage. It's important to balance these properties for optimal performance. Each selection should be reflective of specific industry needs and conditions.

Rubber rolls are versatile tools used across various industries. They are cylindrical components made from rubber, providing both cushioning and support. These rolls find applications in manufacturing, printing, and food processing, among others.

In the manufacturing sector, rubber rolls are crucial in conveyor systems. They help move materials smoothly along production lines. The durability of these rolls can influence overall efficiency. It's important to choose the right type of rubber for specific tasks. In printing, they ensure even ink distribution. This leads to high-quality printed materials, which is vital for businesses aiming for excellence.

Tips: Regular maintenance of rubber rolls is essential. Inspect them for wear and tear. Replace them as needed to avoid production delays. In food processing, these rolls help in packaging, ensuring food safety. Be mindful of contamination risk; the rubber must be FDA-approved. Choosing the right material can minimize this risk.

Another area of application is in the textile industry. Rubber rolls assist in fabric handling and feeding. The right pressure from these rolls ensures that the fabric moves without damage. Monitor the pressure levels; too much can lead to fabric issues. Proper usage of rubber rolls can greatly enhance productivity.

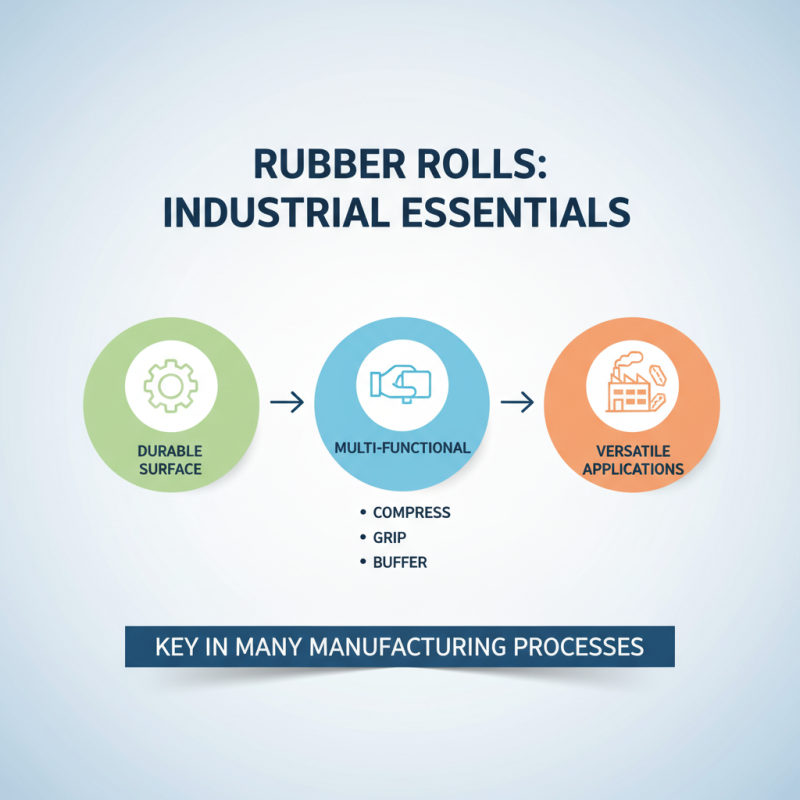

Rubber rolls are essential components in many manufacturing processes. They provide a durable surface for handling and transporting materials. These rolls can compress, grip, and buffer products effectively. Their unique properties make them versatile for various applications in different industries.

Using rubber rolls can greatly enhance efficiency. They reduce the risk of product damage during transit. The cushioned surface minimizes vibrations and shocks. Additionally, rubber rolls offer excellent traction, preventing slippage of materials. This can lead to a smoother workflow and less downtime. However, choosing the right type of rubber roll remains a challenge. Different materials may work better for specific applications.

The benefits extend beyond just performance. Rubber rolls can reduce noise levels in environments where loud machinery operates. This creates a more pleasant workspace. They can also be customized in size and hardness, adding to their appeal. Yet, it’s crucial to regularly assess their condition. Worn rubber rolls can disrupt production and lead to costly repairs. Regular maintenance is key to maximizing their effectiveness.

Rubber rolls are essential components in various industries. They are used in processes like printing, laminating, and coatings. To ensure their efficient operation, maintenance and care are crucial. Rubber rolls can suffer from wear, damage, and contamination. Regular inspection is vital. According to industry reports, about 15% of machine downtime is caused by roll issues.

Cleaning rubber rolls is a fundamental part of maintenance. The frequency of cleaning depends on usage. For high-traffic applications, cleaning should occur daily. A simple solution of warm water and mild detergent often suffices. In some cases, specialized cleaners may be necessary. Neglecting cleanliness can lead to significant performance declines. Statistics show that unclean rolls can reduce efficiency by up to 30%.

Routine inspections can identify early signs of wear. These rolls may develop cracks or harden over time. Applying the right lubricant helps maintain flexibility. Industry data suggest that proper lubrication can extend the roll's life by up to 20%. However, not all lubricants work equally. Testing and assessment should guide selection. Taking these steps could save costs and improve productivity, yet many still overlook them. Keeping an eye on these details is essential.

| Dimension | Material Type | Common Uses | Maintenance Tips |

|---|---|---|---|

| Diameter: 4 inches | Natural Rubber | Printing and Coating | Regular cleaning, proper storage away from direct sunlight |

| Diameter: 6 inches | Synthetic Rubber | Textile Processing | Inspection for wear, lubrication to reduce friction |

| Diameter: 8 inches | EPDM Rubber | Roller Conveyors | Check for damage, avoid harsh cleaning chemicals |

| Diameter: 10 inches | Neoprene Rubber | Food Processing | Sanitize regularly, ensure proper alignment |