-

Home

-

About Us

-

Products

-

Solution

-

Accessories Service

-

Technicial Service

-

Additional Service

-

News

-

Blog

-

Contact Us

Leave Your Message

Rubber rolls have become essential in many industries due to their versatility and effectiveness. According to a report by MarketsandMarkets, the global rubber roll market is projected to reach $3.5 billion by 2025. This growth is driven by increased demand in sectors like manufacturing, printing, and packaging. Industry expert Dr. John Carter states, "Rubber rolls enhance efficiency and reduce operational costs," highlighting their crucial role in production processes.

These rolls are used for various applications, such as material handling, conveyor systems, and printing presses. Their ability to minimize friction and substantial wear can lead to significant operational improvements. However, not all rubber rolls are equal; the choice of materials and construction methods can greatly affect performance.

While the benefits are clear, companies must often reflect on their investment in rubber rolls, as costs can vary widely. Some organizations find themselves grappling with quality issues, leading to unexpected downtimes. This inconsistency in performance reminds us to carefully evaluate suppliers and material choices to ensure optimal outcomes. Emphasizing quality in the selection process can yield long-term benefits in efficiency and cost savings.

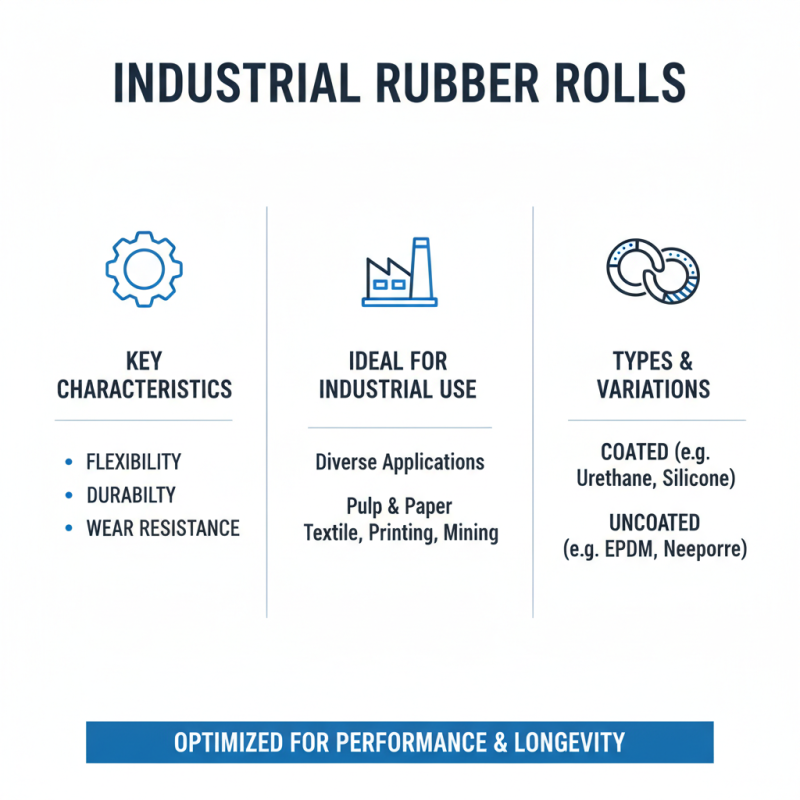

Rubber rolls are vital in various industries, showcasing unique characteristics. They often feature flexibility, durability, and resistance to wear. This makes them ideal for industrial uses. Different types cater to specific needs, such as coated or uncoated variations.

Tips: Consider the environment where the rubber roll will be used. Different operating conditions may require various materials for optimal performance.

In printing and manufacturing, rubber rolls assist in transferring ink or materials effectively. Their surface texture significantly impacts production quality. However, improper maintenance can lead to issues, such as uneven wear or degradation over time.

Do not overlook the importance of regular inspections. Small imperfections can grow into significant problems if not addressed promptly. Always prioritize the right type of rubber roll for your application to minimize long-term costs.

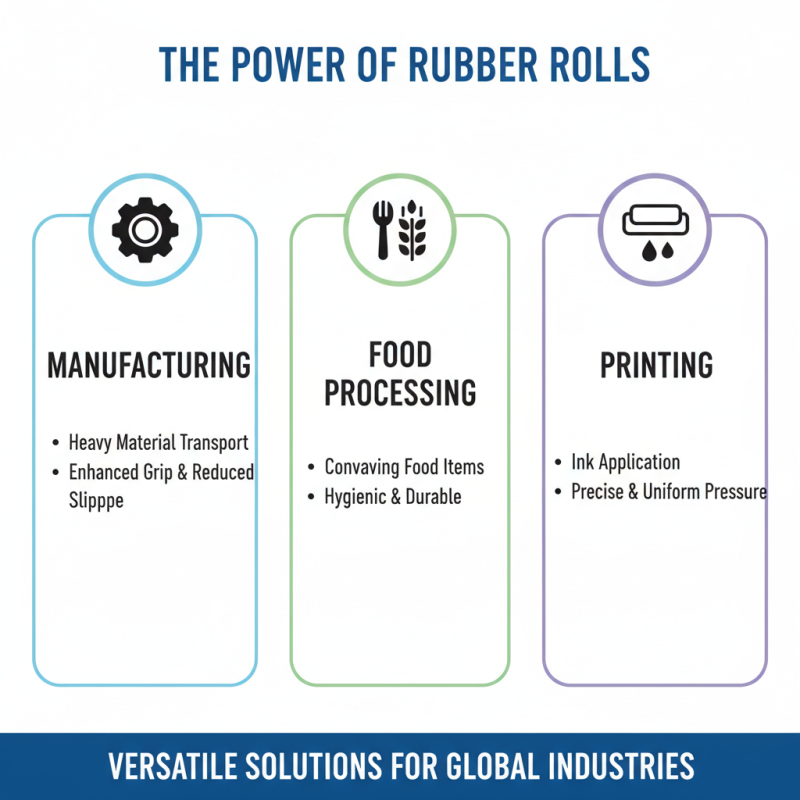

Rubber rolls are important in many industries. They offer unique solutions in manufacturing, food processing, and printing sectors. Each industry utilizes rubber rolls for their specific needs, benefiting from their durability and versatility. For instance, in manufacturing, rubber rolls help in the movement of heavy materials. They provide grip, reducing slippage during transport.

In the food processing industry, rubber rolls are vital in various applications. They help convey food items smoothly through production lines. Their non-toxic nature makes them safe for food contact. Still, the cleaning of these rolls can be a challenge. Regular maintenance and hygiene checks are essential to prevent contamination.

**Tips:** Always inspect rubber rolls for wear and tear. A small crack can lead to bigger issues. Ensure proper cleaning schedules are maintained. This will extend the lifespan of the rolls. Utilizing the right type of rubber for specific applications can improve efficiency.

Printing industries also rely on rubber rolls for consistent quality. They transfer ink accurately, ensuring even coverage. However, choosing the wrong rubber composition can affect print quality. Finding the right balance is crucial. Be prepared to adjust based on the type of print job.

Rubber rolls play a crucial role in various manufacturing processes. They offer a unique combination of flexibility and durability, making them ideal for numerous applications. According to a recent industry report, the global rubber roll market is expected to grow at a CAGR of 5.3% through 2028. This growth highlights the increasing demand for efficient and reliable manufacturing solutions.

One significant advantage of rubber rolls is their ability to reduce noise and vibration. In many environments, this can lead to improved worker comfort and lower maintenance costs. For instance, in the printing industry, rubber rolls help achieve better print quality by ensuring smooth material flow. This results in fewer printing defects and material waste. Additionally, rubber rolls can withstand high temperatures, which is essential in processes involving heat-sensitive materials.

However, there are challenges and limitations. Not all rubber compounds are suitable for specific applications, which can lead to inefficiencies. The wrong choice of material may result in rapid wear, affecting productivity. Furthermore, while rubber rolls offer considerable benefits, their environmental impact during disposal needs solid consideration. Manufacturers must balance performance with sustainability, guiding future developments in rubber technology.

Rubber rolls play a crucial role in the printing and textile industries. These rolls help transfer ink and patterns onto various surfaces. Their surface texture and composition can significantly impact the quality of prints. For instance, a softer rubber roll can provide a more even ink distribution, but it may wear out faster. On the other hand, harder rolls tend to last longer but might sacrifice some print quality. Balancing these attributes can be challenging for manufacturers.

In textile applications, rubber rolls are essential for processes like dyeing and finishing. They help in applying consistent pressure, which ensures uniform dye coverage. However, improper maintenance can lead to issues like staining or inconsistent patterns. Regular inspections are needed to avoid such problems. Some manufacturers find that their rolls degrade faster than expected. This can be a costly oversight. Investing in quality rolls and maintenance routines is vital for longevity and efficiency. It's a continuous cycle of improvement.

Innovative uses of rubber rolls in transportation and handling have emerged across industries. According to a recent report from the International Rubber Study Group (IRSG), the global rubber market's growth is driven by advancements in material technology. In transportation, rubber rolls are increasingly used on conveyor systems and loading docks. They provide a smooth, durable surface for transporting goods. This reduces damage to products and enhances operational efficiency.

In the logistics sector, rubber rolls improve safety and productivity. Their non-slip surfaces help prevent accidents during loading and unloading. Industry data indicates that warehouses with rubber roll systems report a 30% reduction in workplace injuries. Additionally, rubber rolls can absorb vibrations effectively, prolonging equipment life and reducing maintenance costs. Yet, some facilities still rely on conventional materials, missing out on these benefits.

Ultimately, the adoption of rubber rolls requires careful consideration. Facilities must assess their unique needs and potential challenges. Scaling operations with rubber rolls can be a learning curve. Incorporating them effectively often requires strategy and adjustment. Proper implementation is essential to maximize their advantages in transportation and handling. Enhanced performance in logistics can lead to significant operational improvements over time.

| Industry | Application | Benefits |

|---|---|---|

| Manufacturing | Conveyors & Machinery | Durability, Noise reduction, Vibration dampening |

| Transportation | Roller beds and rollers | Improved load handling, Less friction, Wear resistance |

| Agriculture | Seeders and harvesters | Enhanced grip, Reduced soil compaction, Increased efficiency |

| Logistics | Material handling equipment | Easy movement of goods, Minimization of damage, Cost-effectiveness |

| Food Processing | Processing and conveyor rollers | Non-toxic materials, Easy cleaning, Streamlined operation |