-

Home

-

About Us

-

Products

-

Solution

-

Accessories Service

-

Technicial Service

-

Additional Service

-

News

-

Blog

-

Contact Us

Leave Your Message

When it comes to selecting the right Rubber Roll, expert insights are invaluable. John Smith, a leading consultant in the rubber industry, once said, "The right Rubber Roll can make or break your project." This vital piece of equipment can affect performance and longevity in various applications, including manufacturing and logistics.

The market offers a wide range of Rubber Rolls, each tailored to specific needs. Choosing poorly can lead to inefficiencies and increased costs. Different hardness levels, sizes, and materials make the selection process complex. It's easy to feel overwhelmed, especially with so many options available.

Understanding your unique requirements is crucial. Consider factors like load capacity and surface texture. Reflect on past decisions in your projects; did the Rubber Roll you chose meet your expectations? Whether you seek durability or flexibility, careful consideration is essential. Remember, a well-informed choice is the first step toward success.

When selecting a rubber roll, understanding the types available is crucial. Different applications call for specific characteristics.

For example, solid rubber rolls offer durability and resistance to wear. They are often used in industrial settings. In contrast, foam rubber rolls provide cushioning. They are ideal for applications requiring shock absorption.

Consider the hardness of the rubber. The durometer scale measures this. Softer rubber is better for tasks needing flexibility. Items like workout mats often use softer compounds. Harder rubber is preferred for heavy-duty operations.

These rolls can withstand more pressure.

Look at surface texture as well. Some applications benefit from a smooth surface, while others need a textured finish. A textured roll can provide better grip. Still, it may wear down quicker.

Always weigh your options. As choices increase, so does confusion. Think about your specific needs and how these factors align.

When selecting the right rubber roll, its durability and performance are critical. One should consider the environment where the rubber will be used. Is it indoors or outdoors? Will it face heavy loads? These factors influence the roll's worthiness.

Here are some tips to help you make informed choices. Pay attention to the rubber's durometer rating. It measures hardness and can impact flexibility. A softer rubber may provide better grip but wear out faster. On the other hand, harder rubber lasts longer but might sacrifice traction.

Evaluate the roll's resistance to chemical agents. Not all rubber withstands oils or solvents. If you’re in a workshop, spills are likely. Check how the rubber holds up against common liquids in your workspace. This can be the difference between frequent replacements and long-lasting performance. Don’t overlook warranty offers. They often reflect the manufacturer’s confidence in their product. It’s worth considering.

| Feature | Description | Durability Rating | Recommended Applications |

|---|---|---|---|

| Material Composition | Natural rubber, synthetic rubber, or a blend | High | Industrial equipment, flooring |

| Hardness | Measured in Shore A | Medium | Printing, packaging |

| Temperature Resistance | Ability to withstand extreme temperatures | Excellent | Food processing, medical applications |

| Surface Texture | Smooth, textured, or patterned | Varies | Conveyor belts, anti-slip surfaces |

| Chemical Resistance | Resistance to oils, acids, and solvents | Good | Automotive, manufacturing |

| Compression Set | Ability to return to original shape after compression | Low | Seals, gaskets |

| Color Options | Range of colors available | N/A | Aesthetic applications |

| Weight | Weight per linear foot | Varies | Transportation, logistics |

| Customization Options | Sizes, shapes, and finishes | N/A | Special projects |

| Cost | Price per unit in comparison to performance | Average | Budget considerations |

When selecting a rubber roll, weight and thickness are crucial factors. The weight often determines durability and stability. Heavier rolls may offer better performance in rigorous applications. However, they can be challenging to handle. A balance is essential. Assess your specific needs carefully.

Thickness plays a vital role as well. Thicker rubber rolls provide more cushioning and resistance. This can be advantageous for various surfaces. But if the roll is too thick, it may not fit your machinery properly. Always measure your equipment’s requirements.

Consider the environment too. If you’re in a high-temperature area, the rubber might react differently. This could affect durability over time. Remember, a wrong choice can lead to operational issues. Reflect on all factors before making a decision.

Choosing the right rubber roll requires a deep understanding of specific application needs. Different industries demand different properties, such as hardness, resilience, and surface texture. According to a recent market report, nearly 40% of production inefficiencies stem from inappropriate material selection. This highlights the importance of assessing your unique requirements before making a decision.

For instance, a roll used in printing may need a softer surface to achieve reliable ink transfer. In contrast, rolls used in manufacturing heavy machinery must withstand high pressure and abrasion. The industry standard for hardness ranges from 30 to 90 Shore A; selecting the correct hardness can significantly impact performance. Furthermore, nearly 60% of users overlook compression set data, which affects stability over time.

It is also vital to consider the environmental factors at play. Temperature fluctuations and exposure to chemicals can degrade rubber quality. A survey revealed that 70% of companies failed to account for these elements, leading to premature failures. Reflecting on these aspects ensures a more informed choice that aligns with operational goals.

This chart outlines the key factors to consider when selecting a rubber roll for specific applications, rated on a scale of 1 to 10 based on their importance.

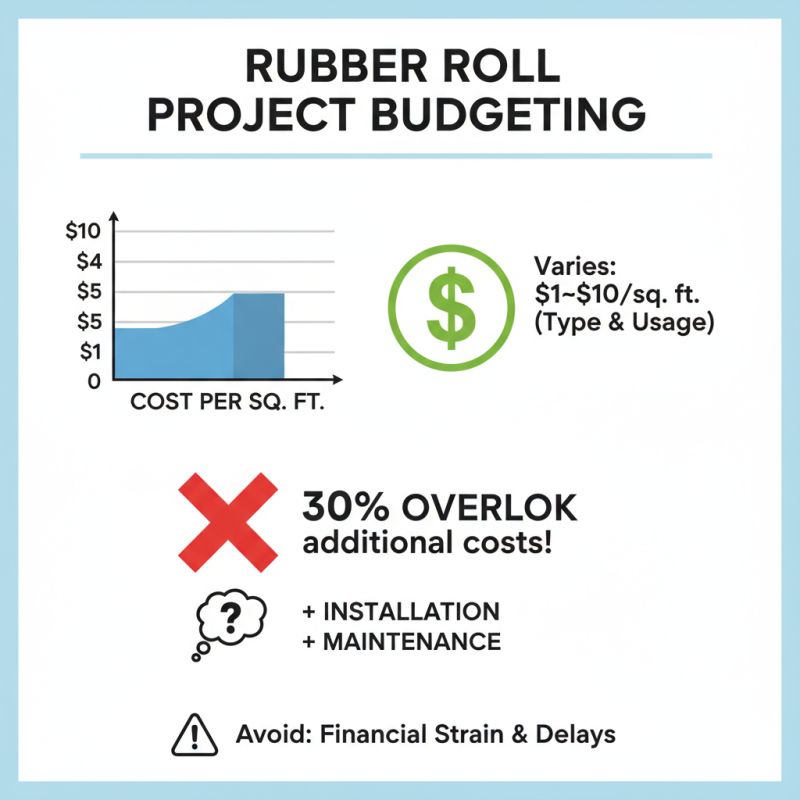

When choosing rubber rolls for your projects, budgeting plays a crucial role. The cost of rubber rolls can vary greatly, from $1 to $10 per square foot, depending on the type and usage. Reports indicate that 30% of project managers fail to account for additional costs, such as installation and maintenance. This oversight can lead to financial strain and project delays.

Understanding your budget means considering both short-term and long-term expenses. For instance, lower-priced rubber rolls may save money upfront but could require frequent replacements. A study by the Rubber Manufacturers Association found that high-quality materials can reduce overall costs by up to 15% over five years. A poor choice can result in wasted funds and resources.

Additionally, keep in mind that specialty rubber rolls may offer unique advantages but often come with higher costs. Reports suggest that more than 25% of buyers regret not investigating the full life cycle costs of their materials. Reflecting on these financial aspects helps ensure a more informed decision, allowing for better project outcomes and resource management.